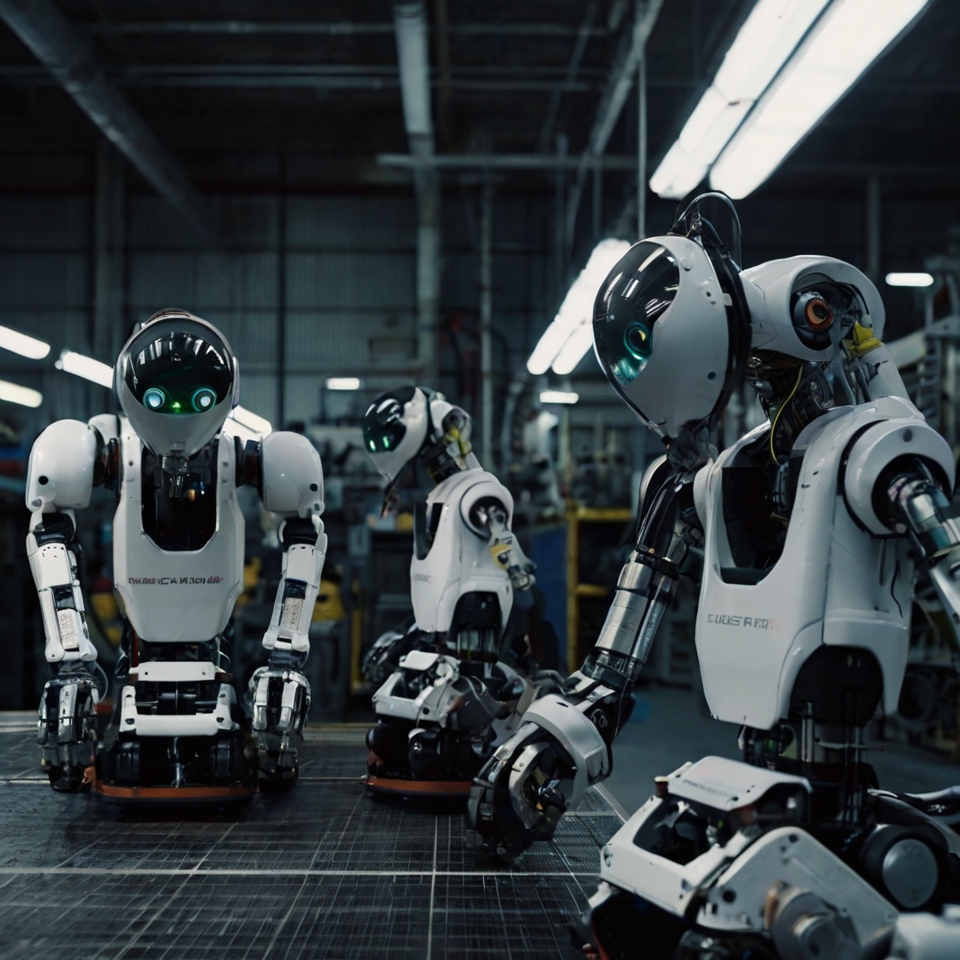

The collaborative robots market is experiencing robust growth, driven by increasing demand for flexible and adaptive automation solutions across various sectors. Unlike traditional industrial robots, collaborative robots, or “cobots,” are designed to work alongside human employees, combining the strengths of human skills with robotic efficiency. By 2031, this market is projected to expand significantly, reflecting ongoing innovation in robotics and the need for safer, more productive work environments.

One of the leading trends shaping the collaborative robots market is the adoption of cobots in small- and medium-sized enterprises (SMEs). Cobots’ user-friendly design, scalability, and lower cost make them an attractive option for smaller businesses looking to implement automation without the high overhead typically associated with industrial robots. Cobots offer the advantage of easy programming, allowing employees with minimal technical expertise to operate them, which makes them accessible to a broader range of companies.

In the automotive and electronics sectors, collaborative robots have become instrumental in improving production workflows. In automotive manufacturing, for example, cobots assist with tasks such as assembling parts and quality control, which improves precision and minimizes human error. Similarly, in electronics manufacturing, cobots are used in circuit board assembly and inspection, where their speed and accuracy contribute to increased productivity. As demand for these industries’ products rises, so does the need for innovative robotic solutions to meet high production standards.

The trend of human-robot collaboration is also driving the adoption of cobots in warehousing and logistics. With the rise of e-commerce, companies are seeking solutions to enhance warehouse efficiency and streamline fulfillment processes. Cobots are used for tasks like sorting, picking, and packaging, where they work alongside humans to meet the fast-paced demands of modern supply chains. This collaboration improves both speed and accuracy in order fulfillment, a crucial factor for companies competing in the digital marketplace.

Safety and regulatory compliance remain essential considerations in the collaborative robots market. As cobots work in close proximity to humans, ensuring their safe operation is paramount. Advances in sensor technology have significantly enhanced the safety features of cobots, enabling them to detect human presence and adjust their actions accordingly.

Compliance with international safety standards, such as ISO/TS 15066, has become a requirement for manufacturers, and as these standards evolve, they will continue to shape the development and deployment of cobots.

Looking forward, the collaborative robots market will likely see more advanced cobots capable of performing increasingly complex tasks. With AI and ML enhancements, cobots are expected to adapt to diverse work environments, making them suitable for industries ranging from healthcare to agriculture. As businesses seek to stay competitive, the integration of collaborative robots into traditional workflows will offer new opportunities for innovation and efficiency, positioning cobots as a cornerstone of the future workforce by 2031.

In conclusion, the collaborative robots market is on the cusp of transformative growth, driven by increasing automation demands, technological advancements, and the potential for improving productivity across multiple industries. As these robots evolve and their applications expand, they will continue to be a vital resource for companies striving to enhance both operational efficiency and workplace safety.