Injection molding has long been a cornerstone of manufacturing, especially in industries such as automotive, medical, and consumer products. As technology advances and market demands evolve, the future of injection molding is set to transform dramatically. This article delves into the emerging trends and innovations that are shaping the future of this critical manufacturing process.

1. Understanding Injection Molding

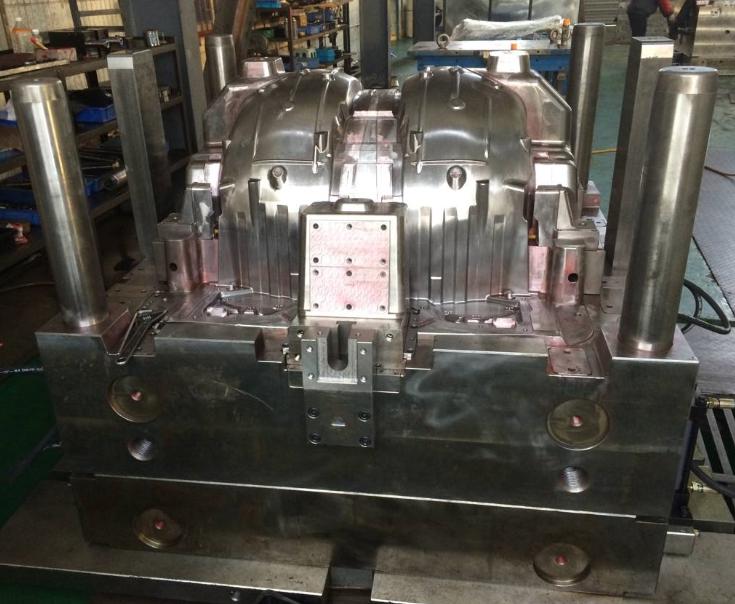

Before exploring the future, it’s essential to grasp what injection molding is and how it works. This manufacturing process involves injecting molten material into a mold to create various plastic parts. Here are some key elements:

- Material Types: Commonly used materials include thermoplastics, thermosetting plastics, and elastomers.

- Process Steps: Key steps include material preparation, injection, cooling, and ejection.

- Applications: Injection molding is used in everything from automotive components to medical devices.

2. Cost-Effective Production Techniques

As the demand for high-quality products at lower costs increases, manufacturers are adopting cost-effective production techniques. This shift is crucial for maintaining competitiveness in the market.

- Optimized Mold Design: Advanced software tools enable precise mold design, reducing material waste and production time.

- Energy Efficiency: New technologies focus on reducing energy consumption during the molding process.

- Material Selection: Choosing cost-effective materials without compromising quality is vital for reducing overall production costs.

3. Innovations in Material Science

Material science is rapidly evolving, leading to the development of new materials that enhance the injection molding process. Innovations include:

- Biodegradable Plastics: These materials are becoming popular due to increasing environmental concerns.

- Recycled Materials: Using recycled plastics not only reduces waste but also lowers production costs.

- Advanced Composites: These materials offer improved strength and durability, making them ideal for demanding applications.

4. Automation and Smart Manufacturing

The integration of automation and smart technologies is revolutionizing the injection molding industry. Here’s how:

- Robotics: Automated systems streamline production processes, enhancing efficiency and precision.

- AI and Machine Learning: These technologies optimize production schedules and predict maintenance needs, reducing downtime.

- IoT Applications: Internet of Things (IoT) devices provide real-time monitoring of machinery, improving operational efficiency.

5. Sustainability in Injection Molding

With growing environmental awareness, sustainability is a significant focus in the injection molding industry. Key initiatives include:

- Waste Reduction: Implementing practices to minimize scrap and waste during production.

- Eco-Friendly Materials: Utilizing sustainable materials that have a lower environmental impact.

- Energy Recovery: Technologies that recover energy during the molding process are gaining traction.

6. Enhanced Quality Control Measures

Quality control remains a top priority in injection molding. Innovations in this area are crucial for ensuring product reliability. Some advancements include:

- Real-Time Monitoring: Continuous monitoring of production parameters helps detect issues early.

- Advanced Inspection Techniques: Technologies like 3D scanning improve the accuracy of inspections.

- Statistical Process Control: This method uses statistical methods to monitor and control the manufacturing process.

7. The Role of 3D Printing

3D printing is increasingly influencing the injection molding industry. Its impact includes:

- Rapid Prototyping: 3D printing allows for quick and cost-effective prototyping of molds.

- Complex Designs: It enables the creation of intricate designs that may be challenging with traditional methods.

- Short Run Production: For low-volume production, 3D printing can be more economical than injection molding.

8. Challenges Facing the Industry

Despite its advancements, the injection molding industry faces several challenges:

- Supply Chain Disruptions: Global events can impact the supply of raw materials.

- Labor Shortages: Finding skilled labor remains a challenge in many regions.

- Technological Adaptation: Adapting to new technologies can require significant investment and training.

9. Future Trends to Watch

Looking ahead, several trends are likely to shape the future of injection molding:

- Increased Customization: As consumer preferences shift, the demand for customized products will rise.

- Digital Twins: This technology allows for the simulation of production processes to optimize efficiency.

- Collaborative Robots: Cobots will work alongside human operators, enhancing productivity.

10. Conclusion

Injection molding is on the brink of significant transformation. By embracing new technologies, materials, and sustainable practices, the industry can meet the evolving demands of the market. As we look to the future, staying informed about these trends will be crucial for manufacturers aiming to remain competitive.

For more insights into the injection molding industry, consider exploring resources on China injection molding and plastic mold solutions.