As we step into 2024, the concept of the smart factory is no longer just a futuristic vision; it’s becoming a reality that’s reshaping the manufacturing landscape. With advancements in technology, smart factories are leveraging automation, artificial intelligence (AI), and the Internet of Things (IoT) to optimize operations and drive efficiency. This year presents unique opportunities and challenges for businesses as they navigate the complexities of this transformative environment.

Embracing Automation

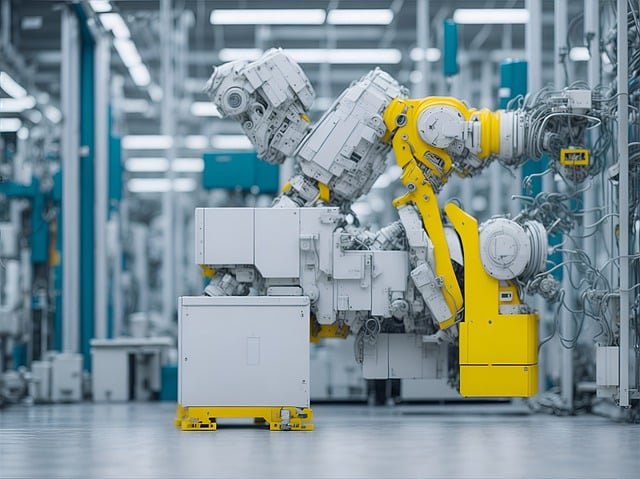

At the heart of the smart factory revolution is automation. In 2024, manufacturers are increasingly investing in robotic process automation (RPA) and AI-driven solutions to streamline production processes. Automated systems not only enhance efficiency but also reduce the likelihood of human error. This shift allows companies to produce higher-quality products at a faster pace, meeting the ever-increasing demand for customization and quick turnaround times.

For many manufacturers, this year marks a significant transition from traditional methods to more sophisticated technologies. Embracing automation means not only investing in new machinery but also in training the workforce to work alongside these technologies. Upskilling employees is crucial, as their expertise will remain indispensable in overseeing and maintaining these advanced systems.

Leveraging Data Analytics

Data is the lifeblood of smart factories. In 2024, manufacturers are harnessing the power of big data analytics to gain insights into their operations. By collecting and analyzing data from connected devices, businesses can monitor performance in real-time, identify bottlenecks, and make informed decisions to enhance productivity. Predictive analytics, in particular, enables manufacturers to anticipate maintenance needs, reducing downtime and lowering operational costs.

However, the journey into data-driven decision-making is not without its challenges. Companies must ensure they have robust cybersecurity measures in place to protect sensitive information from cyber threats. Building a strong data culture that encourages collaboration between IT and operational teams will be key to unlocking the full potential of data analytics.

Sustainability and Compliance

As environmental concerns continue to grow, sustainability is becoming a priority for manufacturers in 2024. Smart factories are uniquely positioned to contribute to greener practices through efficient resource management and waste reduction. Many companies are implementing renewable energy solutions and energy-efficient technologies to minimize their carbon footprint.

Compliance with environmental regulations is also critical. Manufacturers must stay ahead of evolving legislation and standards, which can vary by region. By leveraging smart technologies, companies can monitor their environmental impact in real time and adjust their practices accordingly.

For More Info: – https://www.gmiresearch.com/report/smart-factory-market/

Conclusion

Navigating the smart factory landscape in 2024 presents both exciting opportunities and challenges. As manufacturers embrace automation, data analytics, and sustainable practices, they must also adapt their workforce and address cybersecurity concerns. The journey toward smart manufacturing is a collaborative effort that requires commitment from all levels of an organization. By embracing this transformation, businesses can position themselves for success in an increasingly competitive global market, paving the way for a future that thrives on innovation and efficiency.