Introduction to Tiotropium and Its Production Costs

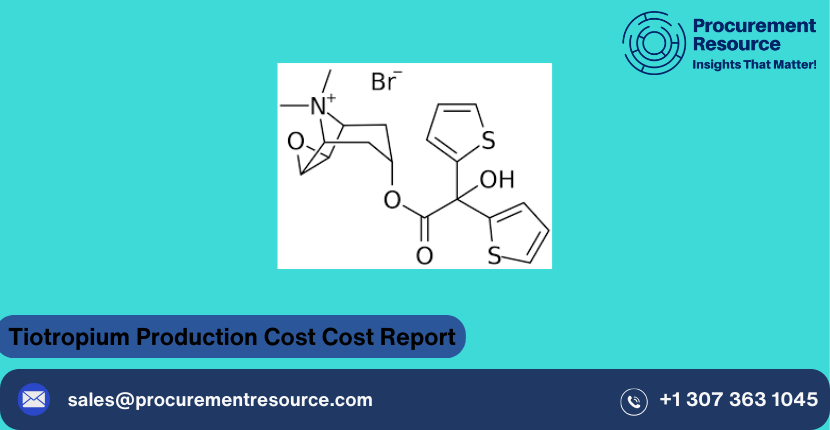

Tiotropium is a long-acting muscarinic antagonist (LAMA) that is used as a bronchodilator in the management of chronic obstructive pulmonary disease (COPD) and asthma. This medication works by relaxing the muscles around the airways, making it easier to breathe. Tiotropium is available in inhalation form and is known for its effectiveness in improving lung function and reducing the frequency of exacerbations in patients.

The production of Tiotropium involves several key steps and factors that significantly impact the overall cost structure. Understanding these components is crucial for manufacturers and stakeholders in the pharmaceutical industry to optimize production processes and maintain profitability. In this article, we will delve into the extensive Tiotropium production cost report, exploring cost models, pre-feasibility analysis, industrial trends, labor charges, utilities, logistics, supply chain considerations, and more.

Extensive Tiotropium Production Cost Report

1. Cost Model for Tiotropium Production

The cost model for Tiotropium production is multifaceted, encompassing raw material costs, labor charges, utilities, and logistics. The primary raw material for Tiotropium is the drug substance, which involves the synthesis of Tiotropium Bromide from precursor chemicals. The cost of raw materials can vary significantly depending on market prices, availability, and quality standards. To accurately determine the production cost, it is essential to account for not only the direct materials but also the costs associated with waste management, quality control, and regulatory compliance.

Labor charges represent a significant portion of the production cost, encompassing the wages and benefits for the workforce involved in both manufacturing and quality assurance. Skilled labor is required to handle sophisticated equipment and to ensure that the manufacturing process adheres to strict quality standards. The labor costs will also vary depending on the location of the production facility and local labor laws.

Utilities, including electricity, water, and gas, play a critical role in the Tiotropium production process. The efficiency of utility usage, coupled with the cost of energy, can significantly impact the overall production cost. Efficient energy use not only reduces expenses but also contributes to sustainability and environmental responsibility.

Logistics and supply chain considerations are also vital in understanding Tiotropium production costs. The transportation of raw materials, finished products, and packaging involves significant expenditure. Efficient logistics planning can help minimize costs associated with warehousing, distribution, and handling, thereby optimizing overall production efficiency.

2. Pre-Feasibility Analysis for Tiotropium Production

Pre-feasibility analysis is an essential step in determining the viability of Tiotropium production. It involves a detailed assessment of the market demand, potential competitors, regulatory requirements, and cost structures. This analysis helps stakeholders make informed decisions regarding investment in Tiotropium production facilities. Factors such as scale economies, expected production volumes, and potential barriers to entry are thoroughly evaluated to ensure that the production plan aligns with market expectations and regulatory standards.

3. Industrial Trends in Tiotropium Production

The pharmaceutical industry is constantly evolving, and Tiotropium production is no exception. Recent industrial trends indicate a shift towards automation and digitalization in the manufacturing process. This trend is driven by the need for cost reduction, efficiency improvement, and quality enhancement. Automation technologies such as robotic arms and computerized systems help streamline production, reduce human error, and increase throughput. Additionally, digital platforms are being utilized for supply chain management, enabling real-time tracking of inventory and production status, which further optimizes the cost structure.

4. Labor Charges and Their Impact on Production Costs

Labor costs can vary widely depending on factors such as region, skill level, and employment laws. In high-cost regions, wages are typically higher, impacting the production cost of Tiotropium. On the other hand, low-cost regions may offer cost savings but could compromise quality and efficiency. It is crucial for companies to strike a balance between labor costs and product quality to maintain competitiveness in the market.

5. Utilities and Their Influence on Tiotropium Production Costs

Utilities are another significant component of Tiotropium production costs. Efficient utility usage not only reduces costs but also supports sustainability efforts. Investments in energy-efficient equipment and renewable energy sources can lower utility expenses and contribute to a greener manufacturing process. The integration of smart grid technologies and energy management systems helps monitor and optimize energy use, further enhancing cost efficiency.

6. Logistics and Supply Chain Considerations

Logistics play a pivotal role in Tiotropium production costs. The global supply chain for Tiotropium involves multiple stages, including procurement, manufacturing, and distribution. Efficient logistics can help minimize delays and reduce costs associated with storage and transport. Integrating a robust supply chain strategy that includes just-in-time inventory management and a reliable network of suppliers and distributors is key to maintaining cost-effectiveness in Tiotropium production.

Request a Free Sample of the Tiotropium Production Cost Report

For an in-depth analysis of Tiotropium production costs, including cost models, pre-feasibility analysis, industrial trends, labor charges, utilities, logistics, and supply chain considerations, Procurement Resource offers an extensive Tiotropium Production Cost Report. This report provides valuable insights into the economic aspects of Tiotropium manufacturing, helping stakeholders make informed decisions.

Contact Us:

Company Name: Procurement Resource

Contact Person: Tom Hanks

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA